Copper Ore Crushed Product Size

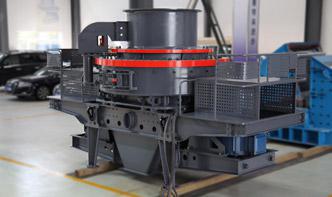

Product size from jaw crusher when crushing. feed size 600mm product size 015mm equipment jaw crusher vibrating screen production line process copper ore material from the vibrating feeder evenly sent into jaw crusher belt conveyor will transport the crushed material to vibrating screen which will separate the materials into three level sizes 05mm 520mm and 20 .